Why Pork Butt Stalls (Stops Increasing in Internal Temperature)

This phenomenon is essentially “porous bed free expansion cooling” or evaporative cooling.

You can equate this concept to Human physiology, we sweat in order to cool our bodies down.

However, when the humidity is high outside, sweat evaporation slows down, meaning it feels hotter.

That’s why they say it’s not the temperature, it’s the humidity that gets you.

As the temperature of the cold meat continues to rise, the evaporation rate increases until the cooling effect balances out the heat input.

The meat then plateaus until all the moisture on the surface is gone.

This is a super important realization because most of the bark formation occurs after the stall.

Yet, most articles, videos, recipes, etc. will tell you to wrap during or even before this happens.

So they’re compromising bark to cook the meat faster.

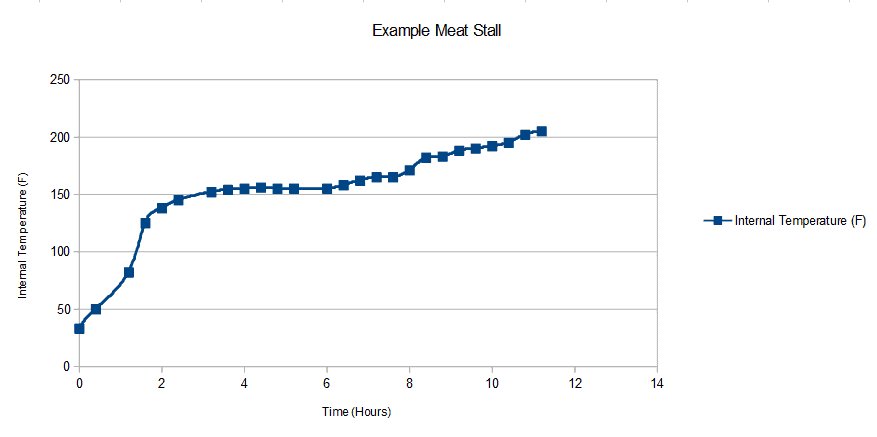

What Temperature Does it Stall at?

At around 150-165F.

But I don’t think you should wrap at this temperature.

In my opinion, this is bad advice because you miss out on creating a better bark – which is the best part of pulled pork.

To illustrate:

Below is a boneless pork butt I smoked and here’s the bark after 3 hours and 30 minutes.

The internal temperature of the pork butt above was ~150F.

Most people would mistakenly believe that they should wrap at this stage – especially if following the regurgitated information found in most articles.

Rather, here’s the pork butt after another 2 hours and 24 minutes.

The bark is noticeably darker. There is a more pronounced “split” on the fat cap; Overall, it just looks far better and likely will taste far better.

My best advice would be to wait longer to wrap.

By waiting longer you allow the meat to take on more smoke, you render more fat, and the bark tastes better.

The internal temperature in the second photo was 170F; I was happy with the exterior and opted to wrap.

How Long will it Last? Why Does the Temperature Go Down?

Around 2-6 hours, usually.

For this article I used a boneless pork butt that weighed 4.12 lbs.

After wrapping, the temperature dropped from 171.7F to to as low as 159F before increasing in temperature.

The time between this photo (when I wrapped):

And the photo below was 1 hour and 50 minutes.

Meaning, my pork stalled for nearly 2 hours and went down in temperature before going back up in temperature.

Both of these processes are completely normal.

How to Beat These Stupid Stalls

You want to wrap the meat to trap humidity (remember that sweating concept?).

The greater the humidity the less we allow the meat to sweat and cool down.

With pork butt, people tend to introduce liquids like apple juice or apple cider vinegar because they add flavor.

While this is true, a more salient point is that the liquids increase thermal conductivity which speeds the cook time.

Liquids – in general – have a better heat carrying capacity than air (roughly 4.2x more).

Meaning, they’ll transfer heat to the meat better.

And again, the liquids steam which adds humidity, preventing the meat from sweating.

Aluminum Foil, Butcher Paper, or Aluminum Pan?

Some folks like to use butcher paper, which is porous.

They use it because it won’t comprise the bark as much due to less steam being trapped.

But if you like to wrap with liquids, this is impossible with butcher paper.

Most people who wrap with liquids use foil pans.

To the pan they’ll add water, apple juice, apple cider vinegar, even sugar water.

As the pork butt continues to push past the stall it will braise and steam in this liquid.

For pork butt I stick to Aluminum foil or aluminum pans.

The pans are useful because you:

- wrap in the pan,

- rest in the pan,

- hot hold in the pan,

- pull the pork in the pan, and

- serve from the same pan

I slightly modify the pan wrap because I don’t like the meat sitting in the juices – here’s my method – I basically just use the liquid to steam the meat and to collect juices to add to the pull later.

2 comments

Karl

Best science and experimentation based description of smoking a pork butt. Thank you for writing this

Dylan Clay

Cheers Karl – happy to hear it was useful!