All beef jerky sold commercially is “cooked” in some capacity.

Meaning, the beef jerky reaches an internal temperature at which the pathogens reach necessary log reductions to be deemed safe for consumption (concept explained below).

What is a Pre-heat Treatment with Regards to Jerky?

Beef jerky that’s sold commercially must undergo a lethality heat treatment before it is dehydrated.

The USDA/FSIS has strict guidelines for the sale of beef jerky – that documentation is also pretty hard to digest as a home jerky maker.

- You can find said documentation here: FSIS Compliance Guidelines.

- In that document they make reference to “Appendix A” which looks at cooking guidelines for meat and poultry.

From Appendix A, page 10 discusses lethality.

Specifically they note:

“Lethality treatments achieve a specific reduction in the number of Salmonella and other pathogens in the product (i.e., an “X-Log10 colony forming units per gram1 (CFU/g)” reduction).”

Going back to the Jerky Guidelines document:

“For meat jerky, use of the product time-temperature combinations provided in Appendix A, including those temperatures above 158°F in which the time for the desired lethality is instantaneous, should help to ensure the safety of the product.”

Meaning, by pre-heating beef jerky to 158F, we achieve the desired lethality instantaneously.

To quote the USDA’s website:

“The USDA Meat and Poultry Hotline’s current recommendation for making jerky safely is to heat meat to 160 °F and poultry to 165 °F before the dehydrating process. This step assures that any bacteria present will be destroyed by wet heat.”

In my opinion, the reason they state those temperatures is because they realize most Home Jerky makers can’t control for things like Relative Humidity in their oven, water activity level testing of their jerky (aside from visual queues), come-up-temperature (CUT), etc.

Rather, they can achieve internal temperatures easily via a kitchen oven that can be verified via a probe thermometer.

Meaning a blanket statement of 158F for beef is adequate.

What is a “Log” Reduction in Terms of Beef Jerky

A “log-reduction” implies a 10-fold reduction of bacteria after every step.

Beef jerky specifically must achieve a 5.0 log reduction of Salmonella spp. – as well as 5.0 log reductions in other common harmful bacteria – namely E.Coli.

Meaning, a “1-log” reduction would reduce the number of bacteria by 90% – leaving behind 100,000 microbes.

- A 2-log reduction would remove 99%, leaving behind 10,000.

- A 3-log reduction would remove 99.9%, leaving 1,000.

- A 4-log reduction would remove 99.99%, leaving 100.

- A 5-log reduction is then 99.999%, leaving 10.

Why Most Dehydrators Result in “Undercooked” Beef Jerky

Most dehydrators will have a range of temperatures that go from ~86F to 165F.

I can tell you from personal experience that most won’t reach near an ambient temperature of 158F; Meaning, how can the meat ever reach 158F?

It can’t, and won’t.

I’d strongly urge you to take an ambient temperature probe and test your own dehydrator. I’m almost willing to guarantee that it doesn’t reach the ambient temperatures it states.

This is likely why the USDA recommends a pre-heat treatment before dehydration.

The USDA also cites case studies where-in beef jerky was dehydrated at 145F for 10+ hours – pathogens like E.Coli were still present.

For some reason the lethality treatments above are a point of contention for a lot of people; Often the people who scoff at the above cite Water Activity as the most important factor, yet they also don’t measure that either.

At the end of the day, it’s up to you with regards to your own safety – especially if you’re immunocompromised.

I’ve made jerky both ways for over 15 years and there is quite literally no difference in taste/texture.

Want to Heat Treat Your Jerky? Here’s How

1. Preheat Your Oven to 350F

Most ovens aren’t calibrated well – especially gas ones.

Use an ambient temperature probe to test your oven for accuracy – 375F+ may very well be 350F ambient.

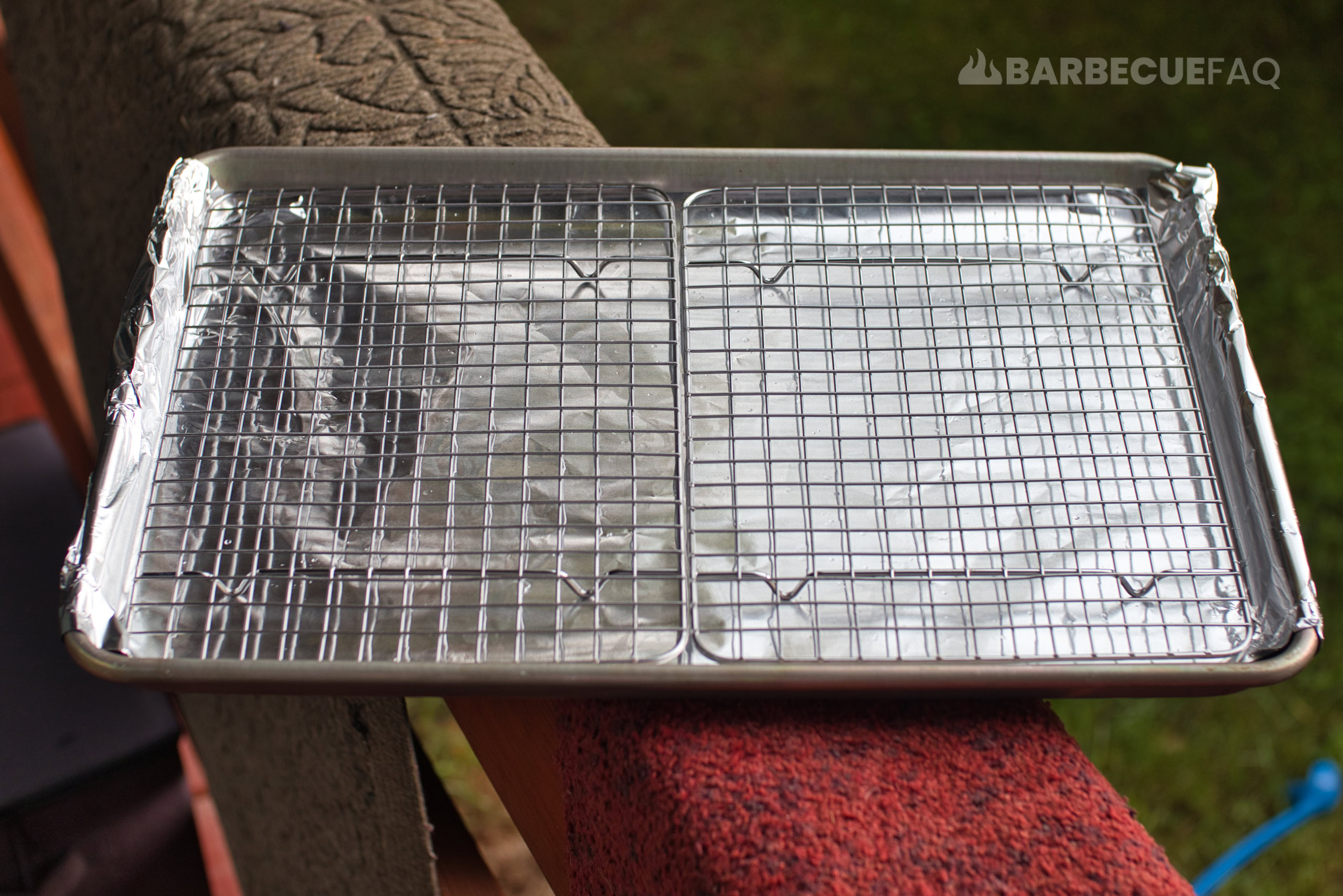

2. Line a Baking Sheet with Foil and Top with Oven Safe Cooling Racks

This elevates the beef jerky off the baking sheet.

I’ve tested not using these cooling racks and what will happen is you’ll case-harden the meat.

Essentially the outside becomes “seared” or “hardened” which prevents the interior of the meat from drying out.

3. Put the Beef Jerky on the Cooling Racks and Ensure None of it Overlaps

I personally DO NOT pat dry my beef jerky.

By patting your meat dry you’re taking away the potential for flavor.

If anything, this pre-heat treatment can function as your “pat dry” or “drip dry” as excess will drip onto the baking sheet.

4. The First Time Doing This, You Can Probe a Piece to See How This Works

Find the thickest piece and probe it.

The goal here is to reach 158F – which instantaneously kills bacteria.

I know from doing this for 15 years, this process takes 10 minutes.

5. After 10 Minutes-ish, Take The Meat Out of the Oven and then Dehydrate

You can dehydrate the meat at around 120-130F (temperatures most commercial dehydrators can actually achieve).

OR 160F which is actually 120-130F ambient in most commercial dehydrators.