“Soft” beef jerky really boils down to ingredients and method.

Click a section to learn more and apply at home:

- Slicing impacts tenderness

- The cut of meat can impact tenderness

- Adding sugar and water to the marinade

- Heat treatment and lower dehydrator temperatures

- Acids and tenderizers in marinade

- Massaging, vacuum tumbling, and more

- Consider ground jerky?

- Why store bought jerky has a leg-up on this concept

This is my preferred style of jerky, so if you found this article just know we’re kindred spirits.

1. The Way You Slice Jerky has a Big Impact on Tenderness

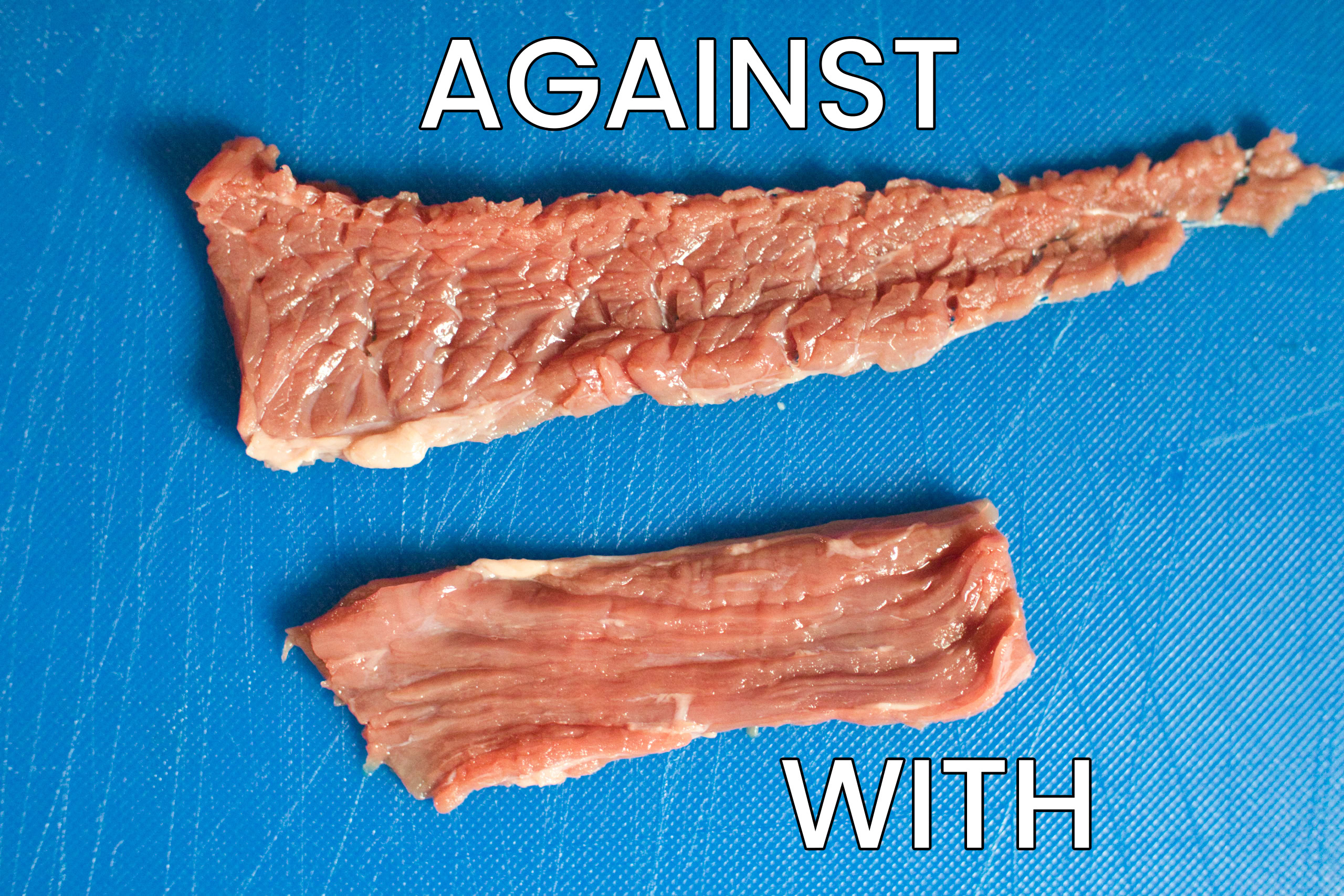

Jerky meat can be sliced 2 ways:

- With the grain

- Against the grain

By slicing against the grain, you shorten these fiber lengths, making it easier for your teeth to separate – meaning the jerky is more tender or “softer.”

By slicing with the grain, you stack these fibers on top of each other, lengthening them.

Meaning, your teeth have to work harder to separate them – meaning the jerky is “chewier.”

To summarize: Cut the meat thin (1/8 – 1/4″ thick) and against the grain.

2. The Beef You Use Matters

Meat for beef jerky is typically:

- Cheap

- Lean

- From heavily exercised muscles on the cow

Most, if not all of those qualities come from the hind legs.

Usually one of the following is used:

- Top round

- Eye of round

- Bottom round

Top round is more tender than the rest, is likely the 2nd most lean, and is usually one of the cheapest options in your grocery store ($4.98/lb-ish).

Most brands use this cut.

I also prefer the size of the roasts they’re cut into.

They’re usually sold as London broils which are easily sliced and require minimal trimming.

To summarize: Use a lean cut like london broil, bottom round, eye of round, brisket flat, flank steak, or round tip.

3. Add Sugar and Water to the Recipe

Aside from Sugar balancing the salt in jerky, sugars are also humectants.

Humectants help with moisture retention and they help to extend shelf life and improve texture.

More or less – sugar binds moisture inside the meat while still keeping the water activity low. The sugar also helps to prevent the moisture from cooking out of the meat.

Some humectants are stronger than others.

Molasses, honey, and dark brown sugar are some of the most common sugars that are used for beef jerky.

Molasses is a stronger humectant than dark brown sugar and will result in completely different texture.

Honey and dark brown sugar will also taste sweeter in the final product, where-as molasses can be bitter.

Adding some water also helps with flavor distribution and helps with moisture retention, making the meat softer.

My regular base marinade features water for this reason alone.

- 1/3 Cup Low Sodium Teriyaki Sauce

- 1/4 Cup Tamari or Low-Sodium Soy Sauce

- 1/4 Cup Water

- 2 Tbsp Worcestershire Sauce

To summarize: If you have a favorite brand of jerky that’s soft, there’s a really good chance it has a good amount of sugar in it. In some cases around 11-13g per serving. Experiment with adding 1/4-1/3 cup of any sugar to a marinade and seeing what happens.

4. Using a Lower Dehydrator Temperature

While heat treatment is a point of contention in the beef jerky world, I do it mainly because I like to dehydrate at a lower air temperature.

I’ll heat treat @ 350F for 10 minutes then transfer to my dehydrator at 122-131 for 4-6 hours for 1-2 lbs of meat.

It results in more even dehydration of the meat creating a more uniform, soft texture.

5. Using Acids and Meat Tenderizers?

The main ingredients you’ll see cited are things like acids and fruits.

The reason fruits are used is because they contain proteolytic enzymes that can break down meat.

Examples of fruits and their respective enzyme:

- Pineapple – Bromelain

- Payapa – Papain

- Kiwifruit – Actinidin

I personally don’t like using fruit – they’re expensive and they make meat taste chalky.

Note: These fruits when canned do not work. This is because these enzymes are effectively destroyed in the canning process.

If You Use Fruits, Reduce Your Marination Time

If you were to allow a marinade with fresh pineapple juice to interact for 24+ hours with the meat, the exterior will essentially turn to mush.

Usually what I’d recommend for most jerky is between 2 – 16 hours; If you use pineapple or any of these ezymes, stick with 2 hours.

Pineapple is also a strong flavor and I’m not big on it.

Acids are Far More Common in Jerky Marinades

Similar to these enzymes, they’re capable of tenderizing meat.

The most common ones you’ll find with jerky are:

- Citrus Juice – Lemon, Lime, Orange

- Wine – Red wine vinegar

- Vinegar – Distilled white vinegar

Similar to the fruits, having these acids interact with the meat for too long will turn the exterior mushy – just less so.

I typically stick to using white vinegar or lemon juice in recipes where I don’t use lots of sugars; Usually 1-2 tbsp is more than enough.

These days, I use citric acid instead because having tons of fresh lemons isn’t realistic.

I use this food-grade citric acid – you only need 1/4 tsp per 1 lb of meat.

6. Massaging, Vacuuming, and Tumbling?

This is another way that commercial beef jerky and homemade beef jerky differ.

At home, you’re apt to marinate your beef jerky by soaking or you’ll put it into a ziplock bag.

In a commercial setting where they’re processing 1,000s of pounds of beef jerky, they can’t wait 16+ hours for the complete saturation of the meat.

Rather, to speed up this process, they’ll use vacuum meat tumblers.

Meat and liquid marinade are added to the tumbler; An external vacuum is then applied. The cylinder is then spun and fins within the cylinder lift and tumble the beef which helps to tenderize it.

As a result – it takes roughly 20-25 minutes for the complete saturation of the meat.

Personally, I find there to be absolutely no taste difference.

This is backed up by case studies too – feel free to read one for yourself.

7. The Case for Ground Beef Jerky

While I don’t make fragmented beef jerky (also called ground beef jerky), I have tasted it and eaten it several times.

All this is, is ground meat that you then make into a jerky-like-shape.

Due to being fragmented (ground) as apposed to being “whole muscle” – it is far easier to chew and is softer in the mouth.

Personally though, I don’t like fragmented jerky as much as I like whole muscle jerky.

Commercial Beef Jerky Ovens Have Humidity, Home Dehydrators Do Not

This section is more or less a ramble for any jerky nerds like me – feel free to ignore or skip or learn something new.

Commercial beef jerky operations make use of specialized ovens that introduce humidity to the environment.

This humidity essentially steams the jerky and over time the humidity is lowered to promote the drying of the product.

Home dehydrators have no humidity – it’s a dry environment that moves warm air over your meat. This causes moisture to be removed from your jerky and you’re left with a shelf-stable meat product.

However, with homemade beef jerky, that means a less consistent texture with regards to “softness” – usually the outside tends to be dryer than the inside.

Why it’s Not Possible to Add Humidity to Home Dehydrating Devices

On most commercial dehydrators it’s not possible to add a water pan (due to space) and because you risk frying the electronics.

On a smoker you’d need to increase the temperature of the device and yet you’d still have no control over the humidity exactly.

The same goes for a home oven; You could do something like rolling up towels, placing them on a baking sheet, and then pouring some boiling water on them.

This is a common strategy that’s used for baking bread.

This will create steam/humidity but again you have no control over it.